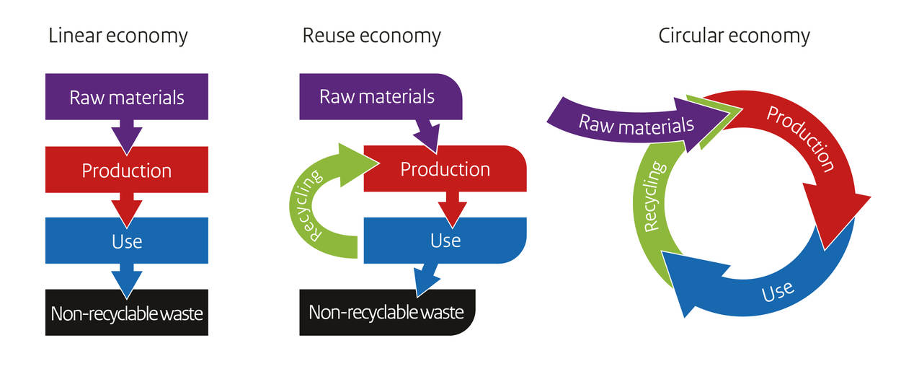

A common approach to production in the past has been a linear one: raw materials were used to make a product and when we had no more use for that product it was thrown away. During each step of production additional waste is created that has to be disposed of. As we became more aware of environmental issues and the growing challenges of finding raw materials, many countries’ economies developed a recycling approach where materials at their end-of-life are collected and brought back into the production chain; for example waste glass is used to make new glass and waste paper is used to make new paper. Even with these improvements, waste is still generated at each stage of the production and this is not addressed in a recycling stream.

There is growing awareness that society must move beyond recycling end products where a lot of material is still ending up as waste. A move toward a more holistic circular economy, where waste is minimized at every step of the production cycle, is supported across Europe and the world. A circular production path means that waste is minimized at each step by making products and materials more efficiently and recovering materials at each stage. If new raw materials are needed, they must be obtained sustainably such that the natural and human environment are maintained.

Structure of linear, reuse and circular economies

A circular economy could increase the efficiency of primary resource consumption both across Europe and the world. By keeping materials that are found in high value products or returning waste to the economy as high quality secondary raw materials, a circular economy would reduce the demand for primary raw materials. In turn, this would help to reduce Europe’s dependence on imports, reducing pressure on the need to import material and protect businesses from the price volatility in the global markets or the supply uncertainty of specific raw materials. There are two elements to a circular economy as outlined by EIT RM: the beginning of the production and waste reclamation. For details see here.

At the concept stage, many key decisions are made which have important and lasting effects for raw materials. In terms of system design in a circular economy, a holistic approach to materials innovation, products, product-service systems, processes and wider systems across the whole lifecycle is necessary. A designer needs to think about the process before they begin. They need to think about how to reduce and reuse waste materials along the production chain.

In a circular economy end-of-life products must be considered as resources for another cycle, while losses and stocks of unused materials must be minimized all along the production chain. In addition, interactions between materials must be considered in order to define the best circular solution. Awareness of the benefits of closing material loops must be raised amongst students, industry and society.

The subject of circular economy can be linked to subjects such as chemistry (waste treatment and transformation of waste into a resource), environment, biology (fertilizers), economics etc.

If, for example, you choose to work with the toolkits “Struvite from urine” or “Phosphorus recover from wastewater”, you can draw a connection with biology and the environment: consider the needs of plants and how they draw nutrients from the soil.

Expand the conversation and link with socio-political issues around safe drinking water and cross- contamination of wastewater and drinking water.

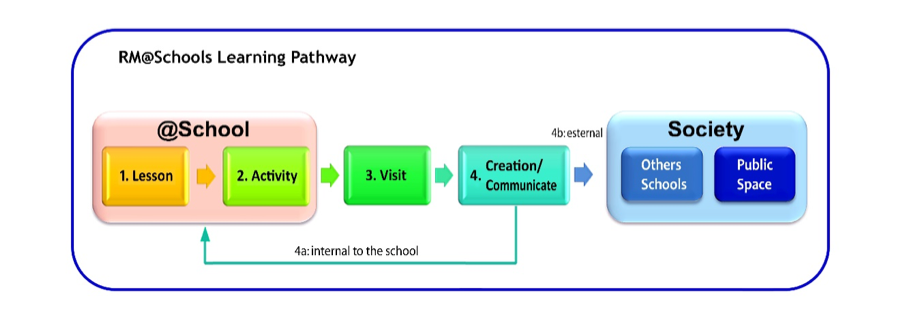

Let’s think about how Toolkits can be used in a learning and teaching setting.

Use the material provided here and in the Circular Economy Toolkits page to develop your initial lesson.

This section provides specific diagrams for cobalt and gallium regarding their resource cycle. Links to source documents are provided.