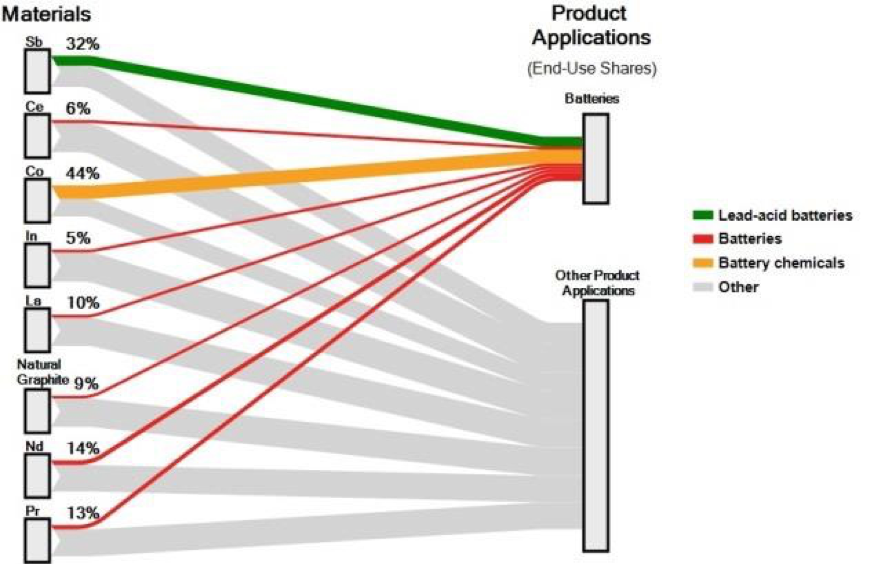

Modern technology relies on highly efficient batteries. Without these batteries smartphones, laptops, electric vehicles and many other modern technologies would not exist. There are many raw materials used in battery production (Figure below). The battery market has seen an increase in the amount of cobalt: from 25% of global end uses of cobalt in 2005 to 44% in 2015, this is mainly due to advances in Li-ion battery technology. As can be seen in Figure 97, 44% of all cobalt production goes directly to the production of batteries.

Percent of CRMs used by the battery sector.

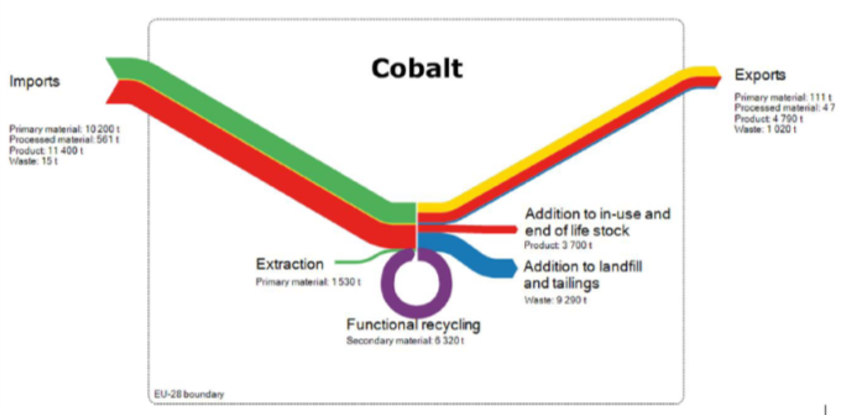

Let’s consider the production stream of cobalt (Figure below).

Simplified Sankey diagram of cobalt.

You can see in that a fair amount of cobalt is recycled back into the production stream (purple circle). There is strong legislation around the disposal of batteries and because of this more batteries are collected, and it is easier for many components to be recycled back into the production chain. The proportion of recycled cobalt is quite high due to the lower costs of the recovered cobalt compared to cobalt extraction from ores, therefore by recycling cobalt the price can be lowered.

Comparing gallium to cobalt, it is easy to see that there is more cobalt being recycled and thus less going into landfills. Generally, cobalt is reused more than gallium (for example) – this result comes from legislation and technologies that allow for the recovery of this element at various stages of the production cycle. The idea of a circular economy is to minimise or eliminate the landfill and tailings contribution (blue line in Figure above) and keep the material in play. Achieving this will make the transition complete from consuming and wasting raw materials to using them sustainably. Keeping raw material in the production chain will allow for the possibility of technological advancement and innovation.