The use of natural earth materials has been crucial to the development and advancement of societies through time. Materials derived from the Earth’s crust are integral to our daily life and have served many purposes in our development. The most basic of these resources found in the Earth’s crust are coal, petroleum and uranium. They have been critical to energy security around the globe. Concentrations of minerals within the Earth’s crust are important for the production of materials necessary for the functioning and future development of society. These may include base metals such as iron, copper, nickel, zinc, tin and lead, important to common metal alloys and essential to global development. Precious metals and diamonds are also mined directly from rocks and throughout history have played a role in the expansion of empires and securing trade. Raw materials sourced from the Earth’s crust are also widely used in infrastructure and construction (cement, building and roofing material) as well as for stone facades and other polished ornamental features in building construction. It should be noted that not all resources involve direct extraction from the Earth’s crust. Some are sourced from living material such as latex used to make natural rubber from the rubber tree and sources of phosphorus from guano (bat dung) and bone meal.

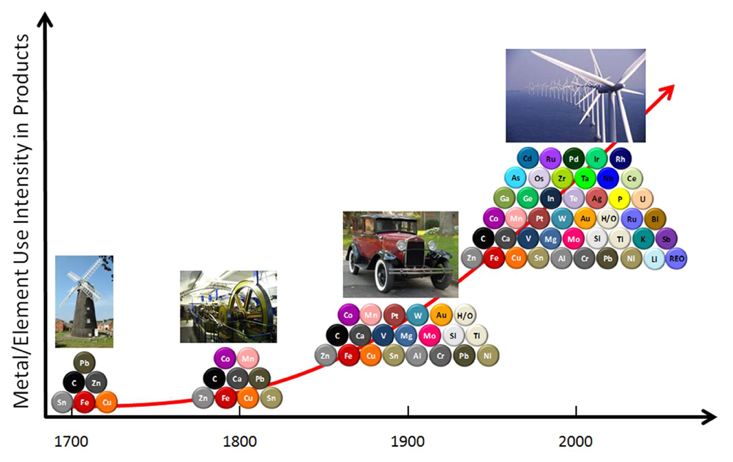

In human history, every technological progress has resulted in the use of increasingly larger quantities and varieties of raw materials. The last leap occurred at the end of the last millennium with the introduction of new forms of renewable energy and with the miniaturization of electronic components. Many of our current technologies (mobile phones, computers, automobiles) and sources of renewable green energy (solar and wind) have become more reliant on metals not commonly mined or openly traded on global markets (i.e. rare-earth-elements, indium, tellurium, germanium and gallium). Scarcity of these raw materials can inhibit development and mass rollout of renewable energy projects to address issues of climate change and the move to a low-carbon economy.

The need for elements found within the Earth’s crust, as technology advances. Source: Markus A. Reuter, Ilkka V. Kojo, Outotec Oyj, Materia2/2012

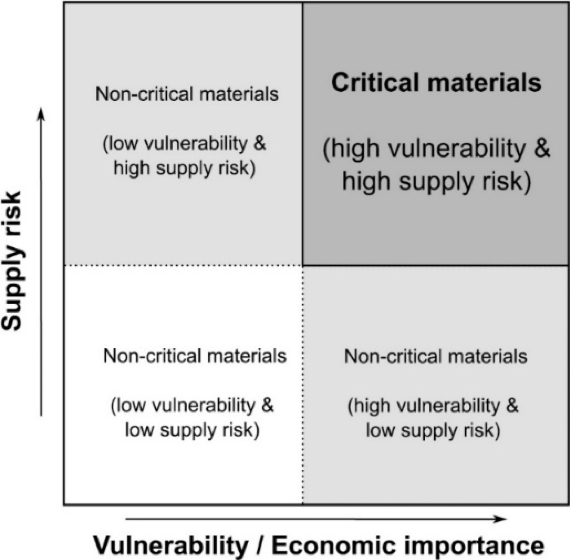

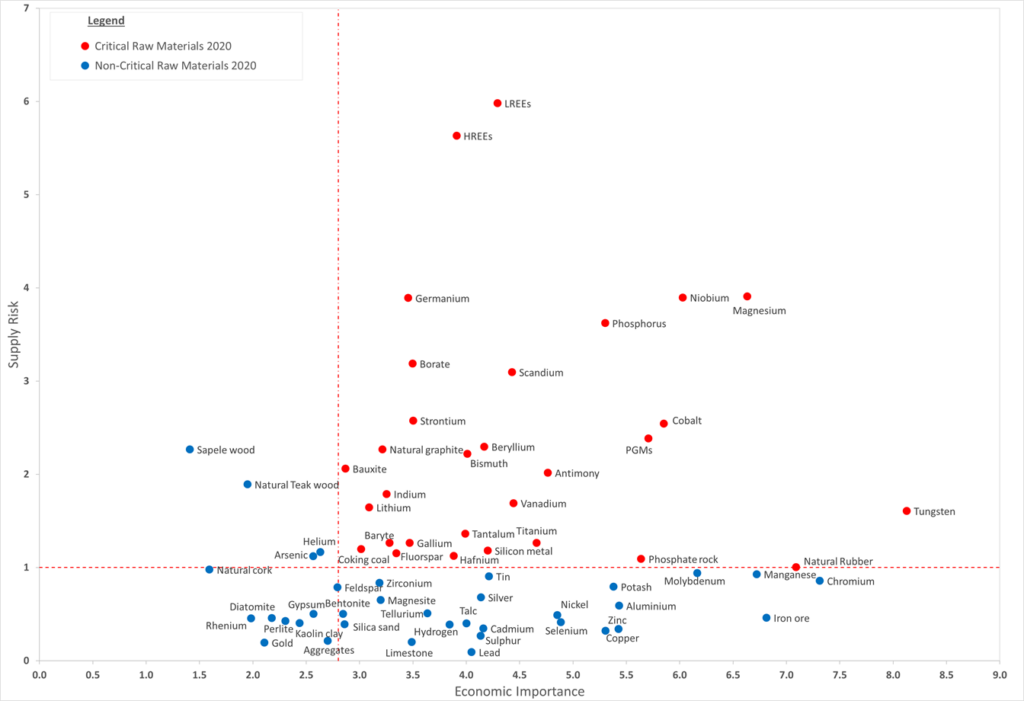

Raw materials are ranked according to the economic importance of the material compared to the risk in accessing the material (the supply risk. If the supply risk is high and the material has high economic importance, then it will be considered a critical raw material for the functioning of the European economy. This list can shift as supply risk or importance change, for example when sources for a material are found or it is substituted by another material. Also, criticality is specific to economic regions of the globe, whereby a raw material critical to Europe would not be defined as such in a producing region (i.e., natural rubber in southeast Asia, cobalt in the Democratic Republic of the Congo). In the Figure below all the red dots represent critical raw materials.

Schematic showing how criticality of raw materials is determined.

2020 European ranking of raw material. Supply risk versus economic importance: Materials highlighted in red are considered critical raw materials. Source: https://rmis.jrc.ec.europa.eu/?page=crm-list-2020-e294f6

Today raw materials have become essential in the manufacturing of common goods and technologies we use every day. Readily accessible raw materials are important to EU industries and for the continued growth of the European economy. The European economy is heavily reliant on raw materials, many of which need to be sourced from regions outside the EU. Where the impact of these raw materials on the EU economy becomes significant, they may be deemed critical and referred to as Critical Raw Materials (CRMs). With the future global resource use projected to double by 2030, addressing raw materials through the entire value chain (sourcing material, use of material and recycling material) becomes a priority.

CRMs are important for many industrial applications and emerging technologies, which through time have become more complex and make use of more raw materials with each new generation of device. This is true in general as society has evolved to make use of more raw materials available in the Earth’s crust and make use of them in more complex combinations.

CRMs are particularly important for high tech products and emerging innovations – technological progress and quality of life are reliant on access to a growing number of raw materials. For example, a smartphone might contain up to 50 different metals, all of which giving different properties such as light weight and user-friendly small size. CRMs are irreplaceable in solar panels, wind turbines, electric vehicles, and energy efficient lighting and are therefore also very relevant for fighting climate change and for improving the environment.

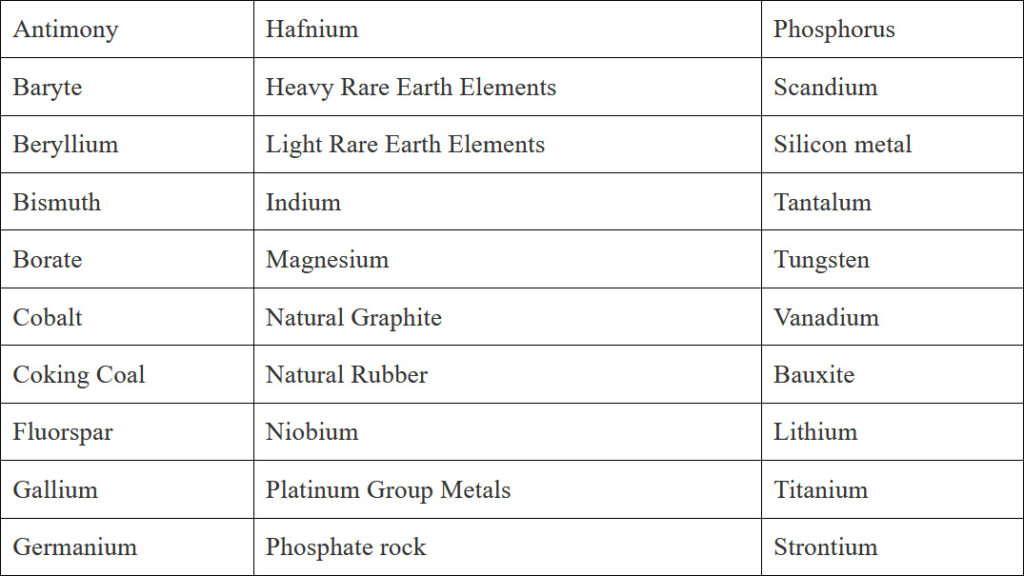

The European Commission pays close attention to the problem of resources because it must import many raw materials which are of strategic importance for its technological and economic development. The EU has determined that there are 30 raw materials that are critical for Europe. It is important to note that raw materials may be deemed critical from a European perspective but for their region of origin these raw materials would not necessarily be considered as critical. The current list of CRMs is not static and can change through time as new resources are found or substitutions found to replace an element’s use in a particular technology or application as well as due to changing global geopolitical scenarios. There are also elements (e.g. lithium and tellurium) that do not currently fall in the critical field for Europe but may become critical as supplies decline or new applications are developed that require more of the raw material.

2020 EU list of Critical Raw Materials. Source: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474

As stated earlier, economic importance and supply risk are the determining factors that identify criticality of a raw material. Impacts of restricted raw material supply would consist of increases in the cost of various technologies, reductions in manufacturing output and difficulties in the adoption of EU policies relying on certain technologies.

Reasons why a material becomes critical

The supply of a raw materials can be at risk due to a variety of reasons. These can be geological, environmental, economic or socio-political:

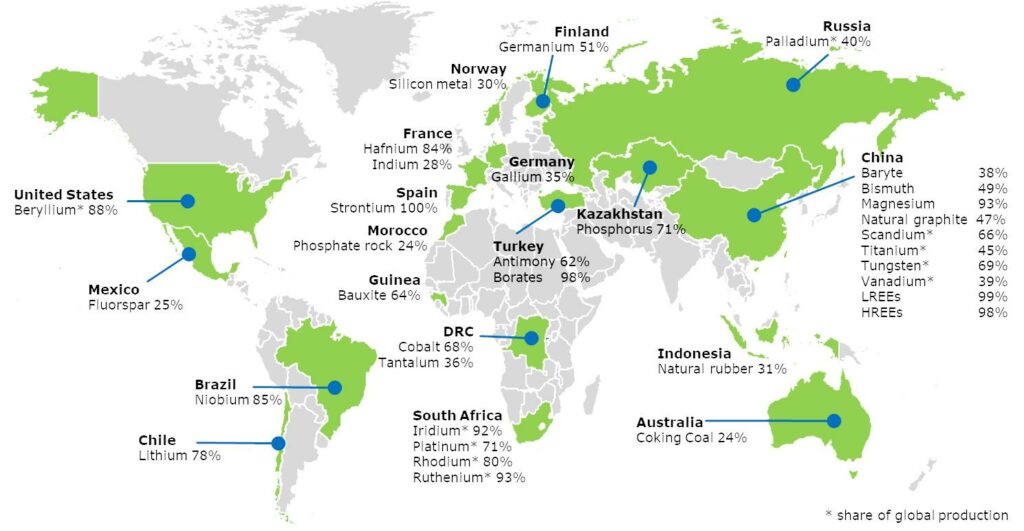

Supply risk arises primarily from the irregular distribution of some raw materials around the globe and is determined by geopolitical boundaries. Because of this, resources can be concentrated within individual nations or regions of the globe. This can result in a monopoly and possible supply restrictions due to environmental or regional political factors. Many of the Earth’s raw material resources are distributed around the globe, such that criticality may not arise (e.g. Cu, Pb, Zn). Those that are not equally distributed run the risk of supply shortages and disruptions. The majority of primary raw materials are produced and supplied by non-European countries. In addition to China, which is the principal supplier of CRMs to the EU, several other countries hold a significant share of the EU supply of specific CRMs, such as the USA (beryllium and helium), Russia (cobalt and scandium) and Mexico (fluorspar and tungsten) (Figure below).

Contribution of countries accounting for largest share of supply of primary CRMs to the EU. Source: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474

For many CRMs the upstream steps of the value chain are not present in the EU: antimony, beryllium, borates, magnesium, niobium, PGMs, phosphorus, rare earths, scandium, tantalum and vanadium. To access those CRMs, the EU has currently no other choice than importing the ores and concentrates or the refined materials from other countries to feed its industries and markets.

Some elements are quite abundant and easily found on Earth, such as aluminium, lead, silicon and potassium (Figure below), while others that are necessary for everyday life such as smart phones and energy storage may be scarce and difficult to source.

If the first two factors are a concern – finding alternatives to replace these materials is a possible solution to the problem. If there is no acceptable substitution, then the material is essential and if it meets one of the other criteria can be considered critical.

In addition, even if the material is abundant, the extraction process may be difficult or environmentally unacceptable. With careful planning and monitoring, many of these concerns can be minimised. The images below depict common associations with poorly managing mining and extraction activities. Pollution, destruction of biodiversity and associated societal and economic costs for local communities can be avoided with appropriate regulation.

In addition, even if the material is abundant, the extraction process may be difficult or environmentally unacceptable. With careful planning and monitoring, many of these concerns can be minimised. The images below depict common associations with poorly managing mining and extraction activities. Pollution, destruction of biodiversity and associated societal and economic costs for local communities can be avoided with appropriate regulation.

Along with environmental considerations the welfare of people must also be considered. In areas with minimal regulation of extraction activities, state and non-state actors can exploit workers. Human rights abuses, child labour and problematic health and safety conditions for labourers have been recorded in countries where little other employment opportunities exist for communities. NGOs and businesses are now coming together to address such issues across their supply chain to eradicate child labour and put in place good practice guidelines for workers. Indeed, ‘conflict minerals’ now extend beyond the issues of the illegal trade of diamonds originating from regions experiencing political upheaval and humanitarian crises. The term ‘conflict minerals’ now applies to metal resources such as cobalt, tungsten, tantalum, tin and gold, where their extraction through illegal practices has negative effects on indigenous peoples and their environment. Tantalum from the minerals columbite and tantalite and colloquially referred to as coltan is illegally extracted in the Republic of Congo to produce components in many of the common electronic devices used by modern society (Figure below).

One of the key shifts in modern society is a shift toward green technologies and low-carbon energy sources. This fundamentally shifts our role from consumer of raw materials to user of raw materials. Raw materials such as wood, coal, oil, petrol, and even uranium are physically consumed during their use and cannot be recovered. However, many components of modern technologies are not consumed (i.e. metals remain metals). Thus, there is the possibility that once a raw material is in the value chain it can foreseeably be maintained, recycled and repurposed. This approach to sustainable use of raw materials is especially useful when considering critical raw materials.

Critical raw materials are identified based on how vulnerable the supply chain is. A range of ores and metals are considered vulnerable. If Europe can source and mine their own metals, this can help reduce vulnerability. Another focus is to be able to recycle material, keeping material in the supply chain instead of it going to waste. This is one of the principles of the circular economy concept. A circular economy is an economic system aimed at eliminating waste and keeping resources within the production cycle. It builds in sustainable design from the inception of a product through the entire life cycle of the product thereby extending the use of materials. In this model, material is not discussed in terms of life-cycle or ‘cradle to grave’ but rather the ideas of reusing, sharing, repairing, refurbishing, remanufacturing and recycling are used to create a closed system, minimizing the use of material and energy resources and the creation of waste, pollution and emissions.

In order to appreciate the challenges critical raw materials pose for economic and technological development we can ask ourselves several questions:

These questions fit into three themes:

These fall within the model of developing a Circular Economy.