[Source: Critical raw materials and the circular economy – Background report 2017 https://publications.jrc.ec.europa.eu/repository/bitstream/JRC108710/jrc108710-pdf-21-12-2017_final.pdf]

Although a large amount of commercial waste is recycled in Europe, end-of-life recycling only satisfies around 10 % of the EU demand for materials. For a number of bulk materials, secondary raw materials satisfy over 30 % of total demand for materials (e.g. copper and nickel). However, for a large number of materials, including almost all critical raw materials (CRMs), the contribution of recycled materials to satisfy the demand for raw materials is still too small. This can be explained by several factors: sorting and recycling technologies for many CRMs are not available yet at competitive costs; the materials are embedded in products kept in use for a long time (e.g. rare earth elements used in wind turbines); demand for many CRMs is growing in various sectors and the contribution from recycling is largely insufficient to meet the demand.

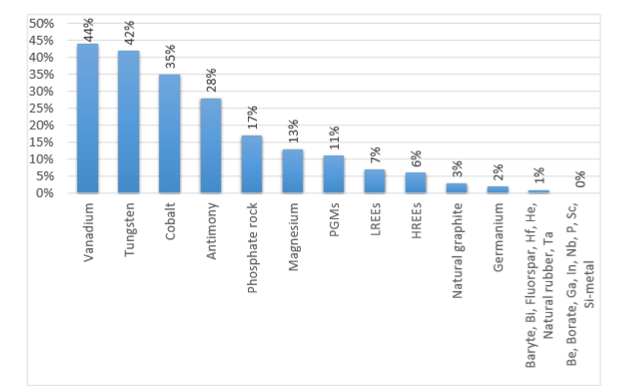

It is worth noting that a few critical raw materials such as vanadium, tungsten, cobalt and antimony have a high recycling input rate. This is because the collection rate at end-of-life is high. Tungsten is mainly used in machine tools and vanadium in steel alloys (both mostly handled by businesses). Commercial businesses have a high recycling rate; cobalt and antimony are used primarily in batteries, these are collected at end-of-life because of waste legislation. Other CRMs have a good rate of recycling at end-of-life (e.g. recycling rates for PGMs reaches up to 95% for industrial catalysts and 50-60% for automotive catalysts) but this gives a contribution that is largelyinsufficient to meet the growing demand and thus the recycling input rate is low (e.g. 11% for PGMs).

Other elements, like indium which is used in flat display panels, have an input rate close to zero as only very small amounts are recycled due to lack of infrastructure and techniques for recycling along with the volatile pricing of the metal.

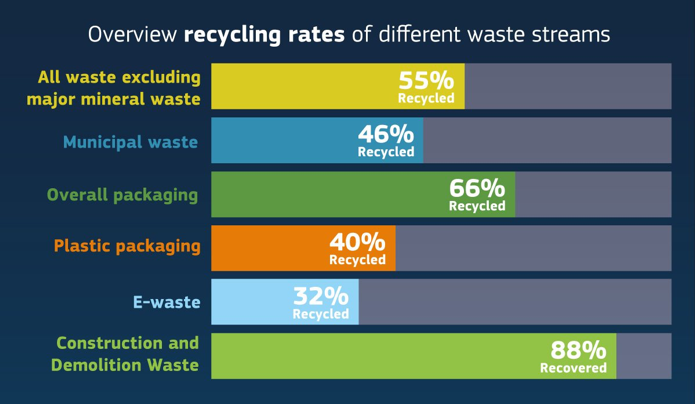

Recycling rates of different waste streams.

It is worth noting that a few critical raw materials such as vanadium, tungsten, cobalt and antimony have a high recycling input rate. This is because the collection rate at end-of-life is high. Tungsten is mainly used in machine tools and vanadium in steel alloys (both mostly handled by businesses). Commercial businesses have a high recycling rate; cobalt and antimony are used primarily in batteries, these are collected at end-of-life because of waste legislation. Other CRMs have a good rate of recycling at end-of-life (e.g. recycling rates for PGMs reaches up to 95% for industrial catalysts and 50-60% for automotive catalysts) but this gives a contribution that is largely insufficient to meet the growing demand and thus the recycling input rate is low (e.g. 11% for PGMs) (Figure 87)[1].

Other elements, like indium which is used in flat display panels, have an input rate close to zero as only very small amounts are recycled due to lack of infrastructure and techniques for recycling along with the volatile pricing of the metal.

Current contribution of end-of-life recycling input rate to meet EU demand.

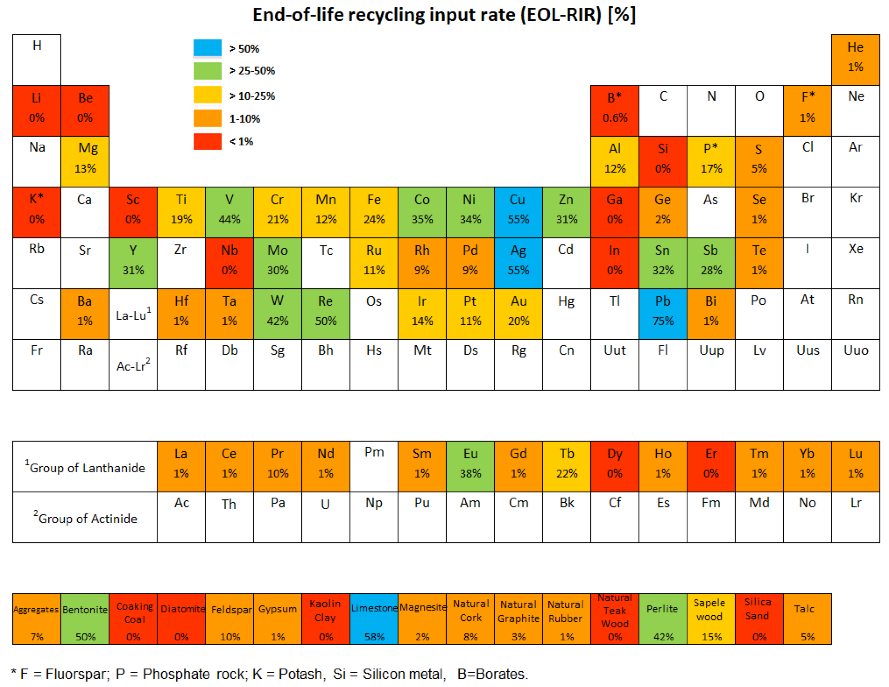

Current contribution of recycling to meet EU demand of CRMs: end-of-life recycling Input Rate (EOL-RIR).